Informazioni di contatto

1-1217, N. 8, Shuntai Plaza, Via Shunhua, Zona ad Alta Tecnologia, Città di Jinan, Provincia dello Shandong

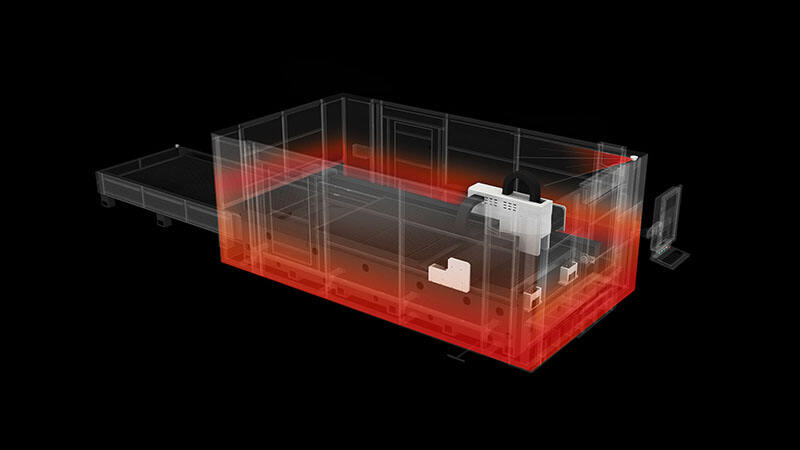

Il prezzo di una macchina per taglio laser su fibre CNC è influenzato da numerosi fattori interconnessi, rendendo fondamentale per i compratori effettuare un'analisi completa delle esigenze prima dell'investimento. I principali determinanti includono la potenza del laser, le dimensioni dell'area di lavoro, il livello di automazione, la reputazione del marchio e le funzionalità aggiuntive. Le macchine di base con sorgenti laser in fibra da 1kW a 2kW e un'area di lavoro standard (ad esempio, 1500mm x 3000mm) partono tipicamente da $30.000 a $50.000, adatte per piccole imprese o applicazioni su metalli sottili (0,1mm a 5mm) nei settori come segnalazione o elettronica. I modelli di gamma media con potenza da 3kW a 6kW, aree di lavoro più grandi (ad esempio, 2000mm x 4000mm) e funzionalità avanzate come teste con auto-foco o software di nesting variano tra $60.000 e $150.000, ideali per la lavorazione di metalli di spessore medio (5mm a 20mm) nella fabbricazione di lamiera o produzione di componenti automobilistici. I sistemi ad alta potenza con laser da 8kW a 15kW, capaci di tagliare metalli spessi (20mm a 50mm), con sistemi di caricamento automatico integrati o capacità 5-asse possono superare i $200.000, mirando alle industrie pesanti come costruzione o cantieristica navale. Il premium di marca impatta significativamente i prezzi: marchi globali di lusso (ad esempio, Trumpf, Amada) richiedono prezzi dal 30% al 50% superiori rispetto ai produttori cinesi (ad esempio, Jinan Linghan) a causa della percepita superiorità tecnologica e delle ampie reti di servizio. Costi aggiuntivi includono il trasporto (dal 5% al 10% del prezzo base), l'installazione, la formazione degli operatori e accessori opzionali come sistemi di estrazione dei fumi o teste di taglio specializzate. I compratori devono anche considerare il costo totale di possesso, compresa la consumazione energetica (i laser in fibra sono del 30% più efficienti rispetto ai modelli a CO2), la manutenzione (costi di servizio annuali ~5% del prezzo della macchina) e eventuali aggiornamenti, per prendere una decisione economica efficace allineata con il volume di produzione, i requisiti materiali e gli obiettivi aziendali a lungo termine.

Copyright © 2025 by Jinan Linghan Laser Technology Co., Ltd. - Informativa sulla Privacy