În procesul de fabricare a țevilor sudate, asigurarea integrității și a calității custurilor este esențială. Detectarea custurii interne joacă un rol crucial în identificarea defectelor potențiale care ar putea compromite performanța produsului final. Acest articol explorează importanța detectării custurii interne, tehnologia din spatele acesteia și impactul său asupra calității tăierilor în producția de țevi sudate.

Înțelegerea Detectării Custurii Interne

Detectarea custurii interne se referă la procesul de examinare a custurii interne a țevilor pentru a identifica orice nereguli sau defecte. Acest proces este esențial, deoarece chiar și defectele minore pot duce la probleme majore, cum ar fi scăderea rezistenței, scurgeri sau chiar eșecuri catastrofale în aplicații unde siguranța este critică. Tehnologia utilizată pentru detectarea custurii interne s-a dezvoltat semnificativ, incluzând metode avansate precum testarea cu ultrasunete și inspecția cu raze X, care permit o evaluare nedistructivă a integrității sudurii.

Importanța Calității Tăierilor

Tăieturile de calitate în țevile sudate sunt esențiale pentru a asigura faptul că produsele finale respectă standardele din industrie și specificațiile clienților. Tăieturile realizate necorespunzător pot duce la nealiniere, compromițând integritatea structurală generală a țevii. Detectarea cusăturii interioare contribuie la menținerea tăieturilor de calitate, asigurându-se că orice defecte sunt identificate și remediate înainte de procesul de tăiere. Această abordare proactivă nu doar că îmbunătățește calitatea produsului, ci reduce și deșeurile și necesitatea de refaceri, economisind astfel costuri pentru producători.

Tehnologii în Detectarea Cusăturii Interioare

Mai multe tehnologii sunt utilizate în prezent pentru detectarea cusăturilor interne, fiecare având avantaje unice. De exemplu, testarea ultrasonică folosește unde sonore de înaltă frecvență pentru a detecta imperfecțiuni în cusătura sudată. Această metodă este deosebit de eficientă pentru identificarea defectelor interne care nu pot fi vizibile din exterior. În mod similar, inspecția cu raze X oferă o imagine detaliată a structurii interne a sudurii, permițând identificarea precisă a defectelor. Integrarea acestor tehnologii în procesul de fabricație asigură faptul că doar țevile sudate de cea mai înaltă calitate ajung pe piață.

Aplicații și beneficii în industrie

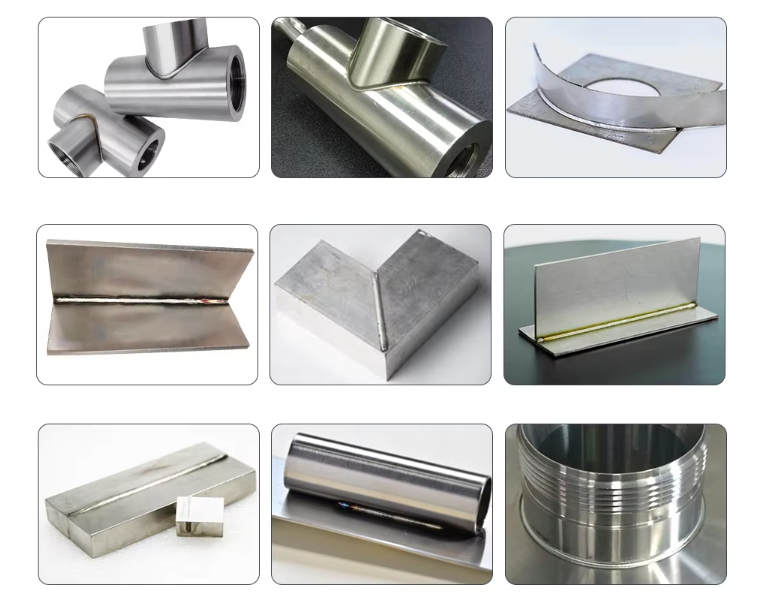

Aplicațiile tuburilor sudate sunt variate, întinzându-se de la industria auto și aerospațială până la construcții și energie. Fiecare industrie are cerințe specifice privind calitatea și performanța tuburilor. Prin implementarea unor sisteme eficiente de detectare a cusăturii interne, producătorii pot asigura conformitatea cu standardele din industrie, pot îmbunătăți fiabilitatea produselor și pot crește satisfacția clienților. Beneficiile depășesc garantarea calității; acestea includ, de asemenea, eficiență operațională crescută și reducerea costurilor de producție.

Trenduri viitoare în detectarea cusăturii interne

Pe măsură ce tehnologia continuă să se dezvolte, viitorul detectării custurilor interne pare promițător. Integrarea inteligenței artificiale și a învățării automate va revoluționa modul în care sunt detectate și analizate defectele. Aceste tehnologii pot oferi monitorizare în timp real și analiză predictivă, permițând producătorilor să anticipeze posibile probleme înainte ca acestea să apară. În plus, accentul pus pe practici de producție sustenabile va stimula dezvoltarea unor metode de detecție mai eficiente, care să minimizeze deșeurile și consumul de energie.

În concluzie, detectarea custurilor interne este esențială pentru asigurarea calității țevilor sudate. Adoptând tehnologii avansate de detecție și menținând standarde riguroase de calitate, producătorii își pot îmbunătăți ofertele de produse și își pot satisface cerințele în continuă evoluție ale industriei. Pe măsură ce piața continuă să crească, anticiparea tendințelor tehnologice va fi esențială pentru succesul în sectorul țevilor sudate.