Kapcsolati információ

1-1217, Nr. 8, Shuntai Központ, Shunhua Út, Magfokozottsági Zóna, Jinan Város, Shandong Megye

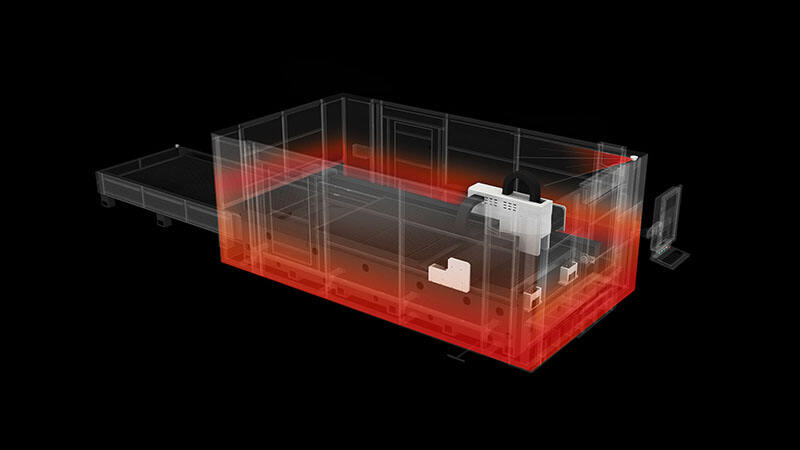

A CNC szalagú laser-vágó egy pontos ipari gép, amely a szalagú laser technológiát és a számítógépes numerikus ellenőrzést (CNC) használja a fémes anyagok nagy pontosságú vágására kiváló hatékonysággal. A gép alapjának közepén egy szalagú lasersz supply található, amely egy lasersugár létrehozására képes optikai szálakon keresztül, és előnyöket kínál, mint például magas energiaátváltási hatékonyságot (legfeljebb 30%), kompakt tervezést és alacsony karbantartást a konverziós CO2-laserekhez képest. A teljesítmény típusosan 1 kW-tól 15 kW-ig terjed, amely lehetővé teszi különbözőféle metállemezek feldolgozását – beleértve a szénhidrogén acélt, rostmentes acélt, alumíniumot, rét és bronzot – 0,1 mm-től 50 mm-ig vastagságban, a paraméterek, mint a lasererő, a vágási sebesség és a segítőgáz típusa (oxid a szénhidrogén acélhoz, nitrógen a rostmentes acélhoz, argon az alumíniumhoz) módosításával. A CNC-rendszer a központi idegrendszerként szolgál, amely a CAD-szerkesztéseket pontos vágási utakra fordítja át, és lehetővé teszi a folyamatparaméterek valós idejű módosítását. Kulcsfontosságú mechanikai összetevők közé tartoznak a magas pontosságú lineáris útmutatók, a tengelymozgás simaságáért felelős szervomotorok, és a dinamikus fókuszdrendszer, amely a lasersugár adaptálása lehetővé teszi különböző anyagvastagságokhoz, így biztosítva a konzisztens vágási minőséget. Az egyéni sebességű modellek legfeljebb 150 méter/percig érhetnek el vékony metállemezeknél, míg a nehéypiros gépek 8 kW-os vagy több laserszel kapcsolhatóak vastag lapok mély behatásokkal. Különféle iparágok számára alkalmas – től a lapacélfeldolgozás és az autóiparig az elektronikától és az orvosi berendezésekig – a CNC szalagú laser-vágó minimális anyagi hulladékot eredményez, csökkenti a pótfeldolgozási követelményeket, és képes olyan bonyolult geometriákat termelni, amelyeket a hagyományos vágási módszerek nem tudnak elérni, ami megteszi azt a modern gyártási automatizáció alapkövévé.

Copyright © 2025 by Jinan Linghan Laser Technology Co., Ltd. - Adatvédelmi szabályzat