Kontaktuppgifter

1-1217, nr 8, Shuntai-platsen, Shunhua-vägen, Högteknologizonen, Jinan-staden, Shandong-provinsen

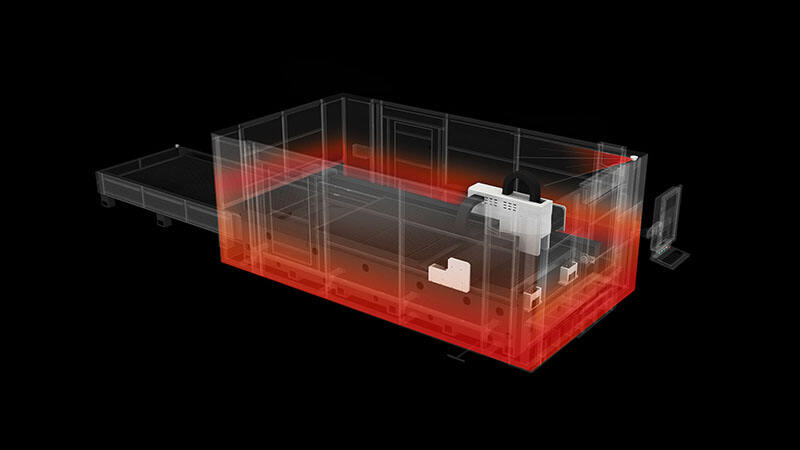

En CNC fiberlaserskärare är en noggrann industriell maskin som utnyttjar fiberlaser teknik och datornumerisk kontroll (CNC) för att uppnå högprecis skärning av metall med exceptionell effektivitet. I grunden använder maskinen en fiberlaserkälla, vilken genererar en lasersstråle genom optiska fibrar, och erbjuder fördelar som hög energikonverterings-effektivitet (upp till 30%), kompakt design och låg underhåll i jämförelse med traditionella CO2-laser. Effektautgångarna ligger vanligtvis mellan 1 kW och 15 kW, vilket möjliggör bearbetning av olika metaller – inklusive kolstål, rostfritt stål, aluminium, koppar och mässing – med tjocklekar från 0,1 mm till 50 mm genom att justera parametrar som lasermakt, skurningshastighet och hjälpgastyp (syre för kolstål, kväve för rostfritt stål, argon för aluminium). CNC-systemet fungerar som det centrala nervsystemet, översätter CAD-designer till preciserade skurningsbanor och möjliggör realtidjustering av processparametrar. Nyckelmekaniska komponenter inkluderar högnoggranna linjära guider, servomotorer för smidig axelrörelse och ett dynamiskt fokussystem som anpassar lasersstrålen till olika materialtjocklekar, vilket säkerställer konstant skurningskvalitet. Högshastighetsmodeller kan uppnå skurningshastigheter på upp till 150 m/min för tunna metaller, medan tunglastmaskiner med 8 kW+ laser hanterar tjocka plattor med djupträngande kapacitet. Lämplig för många industrier – från plattmetallbearbetning och bilindustri till elektronik och medicinska enheter – erbjuder CNC fiberlaserskäraren minimalt materialspill, minskade efterbehandlingskrav och möjlighet att producera komplexa geometrier som traditionella skurningsmetoder inte kan uppnå, vilket gör den till en hörnsten i modern tillverkningsautomatisering.

Upphovsrätt © 2025 av Jinan Linghan Laser Technology Co., Ltd. - Integritetspolicy