Контакт Information

1-1217, бр. 8, Шунтај Плаза, Шунхуа Рут, Хай-тек Зона, град Јинан, провинција Шандонг

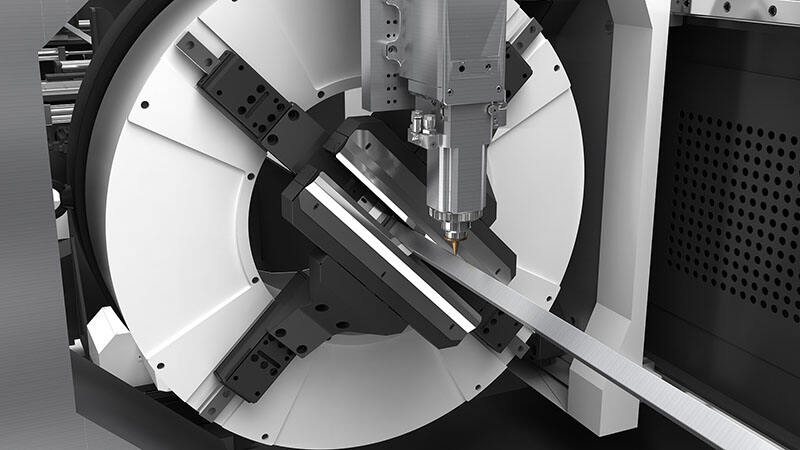

Производител на машини за ласерско сечење на метал е компанија која се специјализира за истражување, развој и производство на опрема за ласерско сечење за разни метали. Поважните производители вложуваат во напредни технологии како што се извори на влакнест ласер, високопрофесионални CNC системи и иновативни механички конструкции за да создадат сигурни и ефикасни машини. Тие нудат различни модели за различни примени: специјалисти за тенки метали, режачи на дебели плочи и решенија за повеќе материјали. Производителите на квалитет користат компоненти од висок квалитет (на пр. извори на ласер IPG или Raycus, линеарни водичи THK) и спроведуваат строг процес на контрола на квалитетот за да осигураат долготрајност. Глобални производители како Trumpf, Amada и Bystronic се познати по премиум машини со проширена сервисна мрежа, додека кинеските производители како Jinan Linghan нудат поефтични решенија со споредлива продуктивност. Поддршката после продажба, вклучувајќи обука, одржување и ажурирања на софтвер, е клучен фактор за разликување, бидејќи осигурува долготрајна сигурност и продуктивност на машините за клиенти ширум светот.

Ауторски права © 2025 од Jinan Linghan Laser Technology Co., Ltd. - Правила за приватност