ข้อมูลติดต่อ

1-1217, เลขที่ 8, อาคาร Shuntai Plaza, ถนน Shunhua, เขตไฮเทค เมือง Jinan มณฑล Shandong

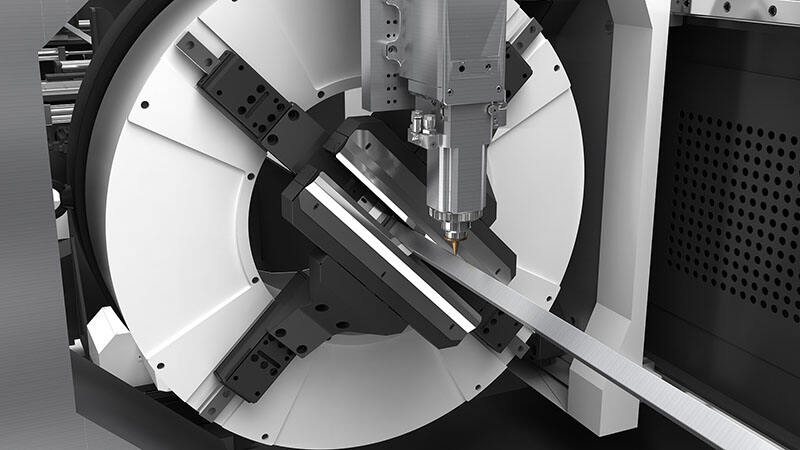

เครื่องตัดโลหะด้วยเลเซอร์เป็นอุปกรณ์ที่มีความแม่นยำซึ่งใช้ลำแสงเลเซอร์ในการตัดวัสดุโลหะหลากหลายชนิดด้วยความแม่นยำและความรวดเร็วสูง โดยปกติแล้วจะประกอบไปด้วยแหล่งกำเนิดเลเซอร์ (แบบเส้นใยหรือ CO2) ระบบควบคุม CNC และกลไกการเคลื่อนที่ที่ทำให้หัวเลเซอร์เคลื่อนที่บนชิ้นงาน เครื่องตัดเลเซอร์แบบเส้นใยเหมาะสำหรับโลหะที่มีความหนาบางถึงกลาง (0.1mm–20mm) เนื่องจากมีประสิทธิภาพการใช้พลังงานสูงและต้องการการบำรุงรักษาต่ำ ในขณะที่เครื่องตัดแบบ CO2 เหมาะสำหรับวัสดุที่หนามากกว่าแต่ต้องการการดูแลรักษาเพิ่มขึ้น ระบบ CNC ช่วยให้ผู้ปฏิบัติงานสามารถเขียนโปรแกรมรูปร่างและลวดลายที่ซับซ้อนได้ โดยมีระบบแก๊สช่วยเหลือ (ออกซิเจน ไนโตรเจน หรืออากาศ) ที่ช่วยให้เกิดการตัดที่สะอาดโดยการขับไล่วัสดุโลหะที่หลอมละลาย คุณสมบัติสำคัญรวมถึงหัวตัดแบบโฟกัสอัตโนมัติ การปรับพลังงานไดนามิก และการควบคุมการเคลื่อนที่ความเร็วสูง (สูงสุด 100m/min) ซึ่งช่วยให้เครื่องสามารถจัดการกับวัสดุหลากหลายประเภท เช่น เหล็กคาร์บอน เหล็กกล้าไร้สนิม อลูมิเนียม และทองแดง ใช้งานอย่างแพร่หลายในอุตสาหกรรมการผลิตแผ่นโลหะ อุตสาหกรรมยานยนต์ อิเล็กทรอนิกส์ และป้ายโฆษณา เครื่องตัดโลหะด้วยเลเซอร์มอบเวลาการผลิตที่รวดเร็ว สิ้นเปลืองวัสดุน้อย และสามารถสร้างการออกแบบที่ซับซ้อนซึ่งวิธีการตัดแบบเดิมไม่สามารถทำได้

Copyright © 2025 by Jinan Linghan Laser Technology Co., Ltd. - นโยบายความเป็นส่วนตัว