2000w Laser welding machine

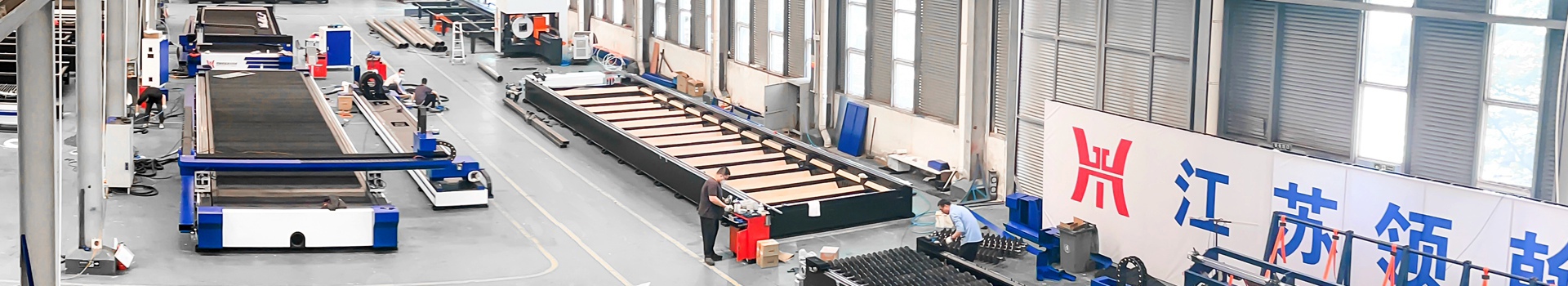

LH Fiber laser welding Machine uses a high-intensity laser beam from a fiber laser to precisely and efficiently weld metal

components together. It’s commonly used in industrial manufacturing, like automotive and aerospace production, due to its accuracy, consistency, and ability to produce narrow and deep welds. Fiber laser welding is a non-contact process, minimizing the risk of contamination or damage to the laser welding machine. This can improve weld quality and reduce the need for post-weld cleaning or refinishing.

- Overview

- Recommended Products

Machine Features:

1. Simple and easy to operate, with no deformation of the weld seam: Stable laser output ensures consistent welding.

2. Equipped with multiple safety alarms, automatic locking of moving parts, and high safety.

3. High power density after laser focusing: Fast speed, deep penetration, and minimal deformation.

4. Compared to traditional welding equipment, the welding is smooth, with no spatter, aesthetically pleasing, fast, and requires no consumables. There are no welding marks or discoloration, and no post-welding polishing is needed.

Product parameters:

Note: All sizes can be customized

| brand name | Leading han |

| Laser source brand | RAYCUS |

| Laser power | 1000w,1500w,2000w,3000w |

| Welding width | 0.2-5mm |

| Head Type | Light Weight Handheld |

| Cooling Type | Water Cooled |

| Control Panel | Touch Screen |

| Maximum wire feed speed | 80mm/s |

| Wavelength range | 1070+20nm |

| Optical fiber interface | QBH |

| Laser Head weight | 0.71KG |

| Effective light aperture | 16mm |

| Spot adjustment range | 0-5mm |

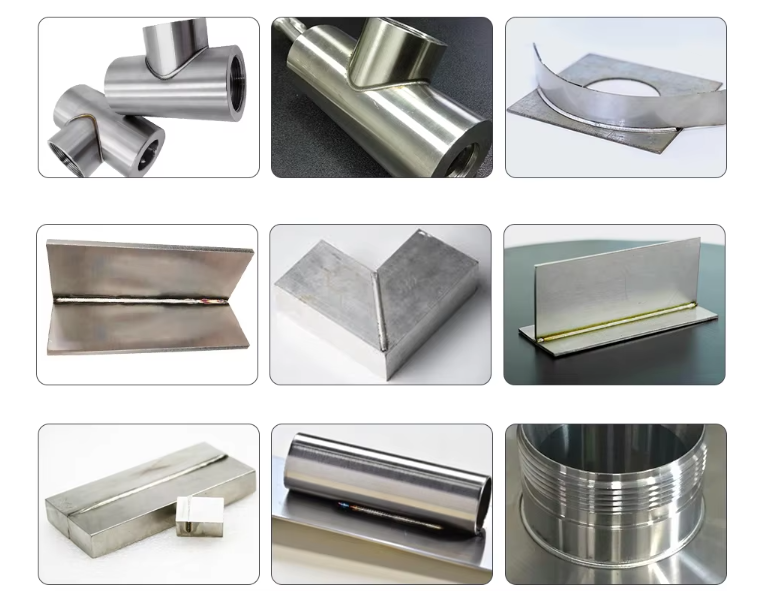

| Applicable Material | Welding of round tubes,square tubes,special-shaped tubes,rectangular tubes, plates, etc. |