Laser Beam Generation and Fiber Optic Amplification

How Fiber Laser Generates and Directs the Laser Beam

Fiber laser cutters work by using special pump lasers to turn electricity into intense beams of light. This light moves through an optical fiber doped with rare earth materials, most often ytterbium. When the light particles (photons) meet excited electrons inside the fiber's core area, something interesting happens. The interaction causes what's called stimulated emission, where each photon creates more photons in a chain reaction. This process makes the light get much stronger, sometimes over 1000 times brighter, yet keeps the beam focused and coherent throughout. The result is a powerful cutting tool that maintains precision even at these extreme intensities.

Pump Laser Diodes and Light Generation

Modern systems combine output from 11–20 pump diodes into a single fiber channel to achieve industrial power levels of 1–10 kW. These diode arrays reach 45–50% wall-plug efficiency, more than three times that of CO lasers (laser-welder.net), making them highly energy-efficient for continuous operation.

Optical Fibre Structure: Core and Cladding

The dual-layer fiber design enables efficient light transmission:

- Core (8–50 µm diameter): Carries the amplified laser light

-

Cladding: Surrounds the core and reflects stray photons via total internal reflection

This configuration minimizes signal loss to less than 0.1 dB/km, allowing stable beam delivery over distances exceeding 100 meters.

Fibre Bragg Gratings for Beam Amplification

Mirror-like fiber Bragg gratings inscribed at each end of the doped fiber form an optical resonant cavity that:

- Selects a narrow wavelength band (1,070 nm ±3 nm)

- Increases power density to 10–10 W/cm²

- Limits beam divergence to under 0.5 mrad

This precise amplification allows fiber lasers to pierce 30-mm stainless steel in under two seconds with ±0.05 mm accuracy.

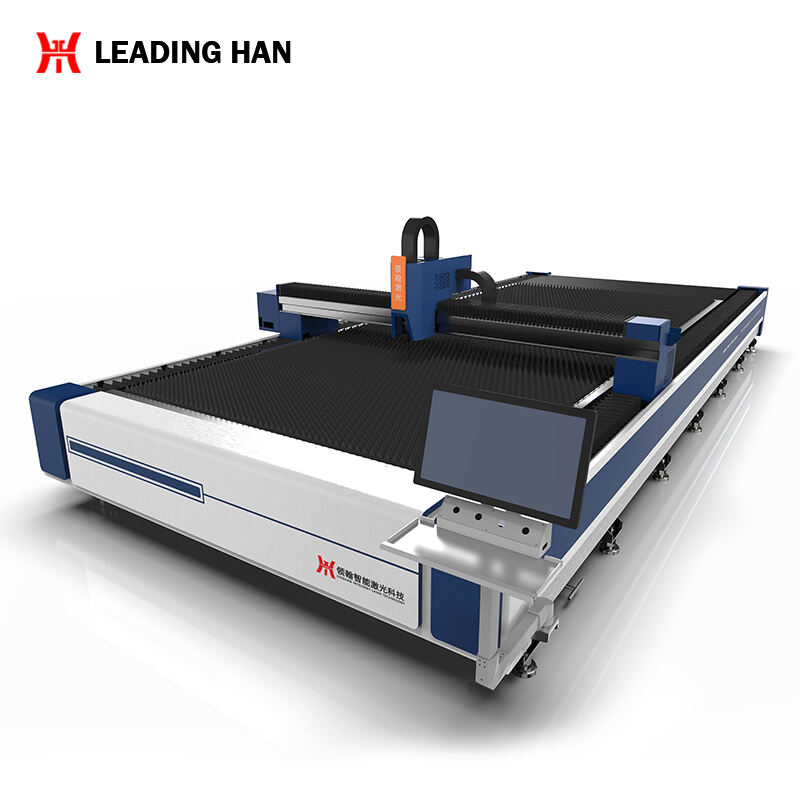

Core Components of a Fiber Laser Cutting Machine

Modern fiber laser cutting machines integrate four key subsystems to deliver micron-level precision in metal fabrication:

Fiber Laser Source and Beam Generation Unit

The core component of this system relies on a rare earth doped fiber, usually containing either ytterbium or erbium materials. When stimulated, these fibers produce a coherent laser beam operating within the wavelength range of approximately 1,060 to 1,070 nanometers. What makes this different from conventional gas lasers is how it works. Instead of relying on bulky gas chambers, the solid state design sends light through flexible fiber optic cables. This not only allows for much smaller installations but also delivers about 30 percent better energy efficiency when compared against older CO2 laser systems that have been around for decades.

Laser Cutting Head, Focusing Lenses, and Nozzle System

The cutting head has these special lenses made out of really pure fused silica stuff that focuses the laser beam down to something tinier than 0.1 mm in size. There's also this coaxial nozzle system that blows assist gases like nitrogen (which needs to be pretty pure, around 99.95%) at pressures between 15 and 20 bar. This helps push out all that molten material while keeping oxygen away from the cut area so we get those nice clean edges everyone wants. Operators actually find this setup works best when they adjust the gas pressure based on what kind of material they're working with.

Role of CNC Systems in Precision Control and Automation

CNC systems basically take those CAD designs and turn them into actual movement paths, achieving repeatability within about 0.03 mm. The controllers in these advanced machines constantly tweak things like laser power which can range from 500 watts all the way up to 30 kilowatts, adjust how fast the cutting head moves (sometimes as quick as 200 meters per minute), and control gas pressure during those complicated five axis movements. This allows for creating really intricate shapes without needing much manual intervention at all. What's impressive is that despite working with big sheets of material, these systems still manage to keep the surface flat within just 0.05 mm per square meter tolerance. That kind of consistency makes a huge difference when manufacturing high quality parts.

Cooling Systems and Machine Frame Stability

Precision requires thermal stability: water chillers keep laser diodes within 25°C±2°C, preventing performance drift during extended operation. The machine frame, often built with granite bases and linear guides, suppresses vibrations below 5 µm, supporting consistent cuts at traverse speeds over 1,500 mm/s.

| Component | Function | Performance Metric |

|---|---|---|

| Laser source | Generates high-intensity beam | 98% wall-plug efficiency |

| Cutting head | Focuses beam & manages gas flow | 0.08 mm focal spot diameter |

| CNC controller | Executes cutting patterns | 0.01° rotational accuracy |

| Thermal stabilizer | Maintains operating temperatures | ±0.5°C tolerance |

This integrated architecture supports accurate vaporization of metals up to 40 mm thick while maintaining 0.1 mm/m positioning accuracy across expansive 3×2 meter work areas.

Mechanism of Melting and Vaporization in Metal Processing

Fiber lasers produce infrared light around the 1,070 nm wavelength, which transfers a lot of heat to whatever material they're working on. When this light hits metal, it gets absorbed by the electrons in the metal's structure, causing temperatures to spike well past what most steels can handle (usually between 1,400 and 1,650 degrees Celsius). The quick jump in temperature leads to both melting and vaporization effects that cut through the material, creating what we call a kerf. For thinner sheets under about 6 millimeters thick, the process works in something called keyhole mode where the laser beam goes straight through and basically turns the metal into vapor right away. With thicker materials though, manufacturers typically switch to a different approach known as melt-and-blow. This method uses continuous wave operation to manage how much material gets removed during cutting operations.

Role of Assist Gases: Oxygen, Nitrogen, and Compressed Air

Assist gases enhance cut quality and speed through three primary functions: ejecting molten material, cooling the heat-affected zone (HAZ), and controlling oxidation.

| Gas Type | Effect on Cutting Process | Best For |

|---|---|---|

| Oxygen | Exothermic reaction adds heat, boosting speed by up to 30% | Mild steel >3mm |

| Nitrogen | Inert shielding prevents oxidation, yielding burr-free edges | Stainless steel, aluminum |

| Compressed Air | Economical option for non-critical applications | Thin sheet metals (<2mm) |

As noted in The Fabricator's 2024 industry analysis, gas pressure (1–20 bar) significantly influences cut quality—higher pressures improve slag ejection but may introduce turbulence. Modern setups use CNC-controlled proportional valves to maintain ±2% pressure stability for optimal results.

Nozzle Function and Gas Jet Dynamics in Clean Cutting

The conical nozzle (0.8–3.0 mm diameter) shapes assist gas into a supersonic jet (Mach 1.2–2.4) that efficiently removes molten metal from the kerf. Critical factors include:

- Standoff Distance: A 0.5–1.5 mm gap protects the nozzle while ensuring effective gas coverage

- Gas Lens Design: Reduces flow turbulence by 62% compared to standard nozzles

- Coaxial Alignment: Requires <0.05 mm alignment between beam and gas stream

Optimized nozzle designs increase cutting speeds by 18% and reduce gas consumption by 22% through improved laminar flow. Integrated piezoelectric sensors detect blockages within 50 ms, preventing approximately 93% of related defects.

Beam Focusing, Precision Control, and Quality Assurance

Focusing the Laser Beam Using Collimating and Focusing Lenses

Collimating lenses work by taking those scattered light rays and lining them up into something closer to parallel before they hit the target. High precision fused silica optics then focus this aligned beam down to a tiny spot size between 0.1 and 0.3 mm. Studies from InTechOpen point out that when it comes to beam quality metrics like BPP (Beam Parameter Product), anything under 2 mm·mrad makes a real difference in cutting accuracy. The result? Stainless steel cuts can be about 30% narrower compared to what's possible with traditional CO₂ laser systems. This matters a lot in manufacturing where every fraction of a millimeter counts.

Nozzle Alignment and Focal Point Optimization

Maintaining a standoff distance of ±0.05 mm between the nozzle tip and focal plane ensures effective melt ejection without beam interference. Capacitive height sensors enable real-time autocalibration during cutting operations. Deviations beyond 0.1 mm can increase dross formation by 60% when processing aluminum, based on 2023 welding trials.

Real-Time Monitoring and Adaptive Control via CNC Systems

Modern CNC systems collect around 1,000 data points every single second during operation. These readings cover everything from gas behavior patterns to how heat affects lenses and where the machine actually is at any given moment. Based on all this information, the system can tweak laser power settings between 1 and 20 kilowatts and adjust travel speeds ranging from just 0.1 meters per minute up to 40 meters per minute within milliseconds. The result? Consistently accurate cuts with tolerances staying within plus or minus 0.1 millimeters even when working on complex shapes and detailed designs. Take variable frequency pulse modulation as an example. When applied to cutting 5mm thick brass sheets, this technique manages to shrink the heat affected zone by almost half compared to traditional methods, making it a game changer for precision work.

AI Integration for Predictive Parameter Tuning and Quality Inspection

Machine learning models trained on more than 10,000 cutting profiles now predict ideal settings for new materials with 92% accuracy. High-resolution vision systems (5-μm resolution) combined with spectral analysis identify micro-defects 50% faster than manual inspection, lowering scrap rates by 18% in automotive production (2024 Precision Machining Report).

Material Compatibility and Industrial Applications

Metals Suited for Fiber Laser Cutting: Stainless Steel, Aluminum, Brass

Fiber lasers operating at around 1 micrometer work really well on shiny metals such as stainless steel, aluminum, and brass. Recent testing in 2024 showed that these laser systems can actually slice through stainless steel plates as thick as 3 centimeters while keeping dimensional accuracy within about a tenth of a millimeter. That kind of precision makes them great for making structural parts needed in buildings and vehicles. When it comes to aluminum alloys commonly found in car body panels, fiber lasers process material about 20 to 25 percent quicker than traditional CO2 lasers do. This speed advantage helps reduce heat damage problems when working with thinner metal sheets, which is important for maintaining quality in automotive manufacturing.

Case Study: High-Precision Cutting in Automotive Manufacturing

Automotive manufacturers employ fiber laser cutters to fabricate chassis parts with 0.05 mm tolerance. A 2023 report highlights how this technology reduces material waste by 18% when shaping high-strength steel door frames. Additionally, adaptive power control during contour cutting achieves a 98% first-pass yield rate in brake component manufacturing.

Future Trends: Aerospace and Medical Device Fabrication Applications

The aerospace industry is seeing growth as fiber lasers get used to work on aluminum sheets for satellites. Meanwhile in medical device manufacturing, these same lasers can cut titanium implants with incredible accuracy down to around 50 microns. Many engineers now rely on fiber lasers when making tiny features on stainless steel surgical instruments too. The finish they get is often under 0.8 microns roughness average without needing any extra polishing steps afterward. With all these advantages, it's no wonder why fiber laser cutting has become so important for developing both advanced clean energy technologies and medical devices that actually work well inside the human body.

FAQ

What is the main advantage of using fiber lasers over traditional CO2 lasers?

The main advantage of fiber lasers is their energy efficiency, which is about 30% better than CO2 laser systems. They also allow for smaller installations and offer precise cutting capabilities.

How do fiber lasers achieve high precision in cutting?

Fiber lasers achieve high precision in cutting through stimulated emission, focusing lenses, and CNC systems that control the laser power, speed, and gas pressure. This precision is maintained even at high intensities.

What are the suitable metals for fiber laser cutting?

Fiber lasers work well on shiny metals like stainless steel, aluminum, and brass, making them ideal for structural parts in industries such as automotive and aerospace.

How do assist gases improve laser cutting?

Assist gases like oxygen, nitrogen, and compressed air help in ejecting molten material, cooling the heat-affected zone, and controlling oxidation, thereby improving cut quality and speed.

Table of Contents

- Laser Beam Generation and Fiber Optic Amplification

- Core Components of a Fiber Laser Cutting Machine

- Mechanism of Melting and Vaporization in Metal Processing

- Role of Assist Gases: Oxygen, Nitrogen, and Compressed Air

- Nozzle Function and Gas Jet Dynamics in Clean Cutting

- Beam Focusing, Precision Control, and Quality Assurance

- Material Compatibility and Industrial Applications

- FAQ